|

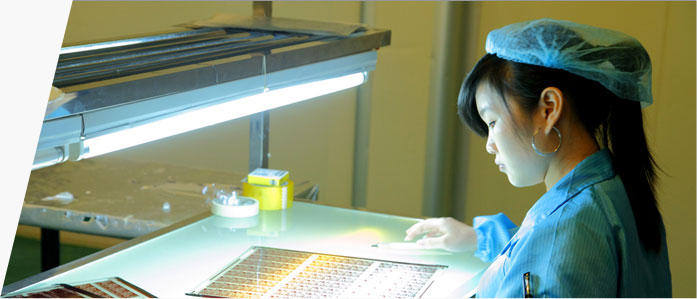

First of all, pay attention to technical training, technical backbone of reserve production operations personnel, and enhance product quality control in a generic sense, in strict accordance with the requirements of the production process, to solve production of defective products from a technical point of view and to improve the quality of the product. First of all, pay attention to technical training, technical backbone of reserve production operations personnel, and enhance product quality control in a generic sense, in strict accordance with the requirements of the production process, to solve production of defective products from a technical point of view and to improve the quality of the product. |

|

Secondly, we must strictly enforce the equipment rules, according to the predetermined frequency equipment routine maintenance. Any found problem should be timely feedback equipment maintenance therapy, reduce poor quality due to equipment failures that result from radically improve product yield. Secondly, we must strictly enforce the equipment rules, according to the predetermined frequency equipment routine maintenance. Any found problem should be timely feedback equipment maintenance therapy, reduce poor quality due to equipment failures that result from radically improve product yield. |

|

|

|

Thirdly, strengthen the wet fluid control, strict control of fluid volume and concentration Medicament added amount of change to test a single instruction guide (according to the procedure code requirements), request the relevant departments to actively cooperate with the syrup concentration, to avoid problems caused by poor quality. Thirdly, strengthen the wet fluid control, strict control of fluid volume and concentration Medicament added amount of change to test a single instruction guide (according to the procedure code requirements), request the relevant departments to actively cooperate with the syrup concentration, to avoid problems caused by poor quality. |

|

Fourth, further strengthen the technical control, modify or change processes according to the actual situation. Fourth, further strengthen the technical control, modify or change processes according to the actual situation. |

|

|

Sunthone is a professional PCB manufacturer, producing quick turn PCB prototypes, samples and small orders.

Impedance Test |

Copper Weight Test |

Ionic Contamination Test |

Laboratory |

Microsection Test |

Peeling Resistance Test |

X-RAY Thickness Test |

Our products have been ISO900, UL certified, trustworthy

UL (Underwriters Laboratories) is an American worldwide safety consulting and certification company headquartered in Northbrook, Illinois. It maintains offices in 46 countries. UL was established in 1894 and has participated in the safety analysis of many of the last century's new technologies, most notably the public adoption of electricity and the drafting of safety standards for electrical devices and components.

UL provides safety-related certification, validation, testing, inspection, auditing, advising and training services to a wide range of clients, including manufacturers, retailers, policymakers, regulators, service companies, and consumers.

UL is one of several companies approved to perform safety testing by the US federal agency Occupational Safety and Health Administration (OSHA). OSHA maintains a list of approved testing laboratories, which are known as Nationally Recognized Testing Laboratories.

Click here to view more information:

http://database.ul.com/cgi-bin/XYV/template/LISEXT/1FRAME/index.html

ISO, the International Organization for Standardization, is an independent, non-governmental organization, the members of which are the standards organisation of the 163 member countries. It is the world's largest developer of voluntary international standards and facilitates world trade by providing common standards between nations. Nearly twenty thousand standards have been set covering everything from manufactured products and technology to food safety, agriculture and healthcare.

Use of the standards ensures that products and services are safe, reliable and of good quality. The standards help businesses increase productivity while minimizing errors and waste. By enabling products from different markets to be directly compared, they facilitate companies in entering new markets and assist in the development of global trade on a fair basis. The standards also serve to safeguard consumers and the end-users of products and services, ensuring that certified products conform to the minimum standards set internationally.

To support relationships between international buyers and Chinese SMEs, we have developed a database with details of all SGS-audited Made-in-China (MIC) suppliers. The database currently contains details of over 10,000 audited suppliers and is continuously being expanded as new suppliers go through the auditing process. Users can search the database by report number, supplier name or location, audit date or date of report validity.

Click here to view more information:

http://www.sgs.com/en/Our-Company/Certified-Client-Directories/Audited-supplier-verification.aspx